Configuration sheet of 2200 Wanlian five-layer corrugated board production line

name | quantity | The main figure | deploy |

Hydraulic paper rack |

5 sets |

| Full hydraulic control, expansion chuck, pneumatic brake. |

Automatic paper feeder | 5 sets |

| |

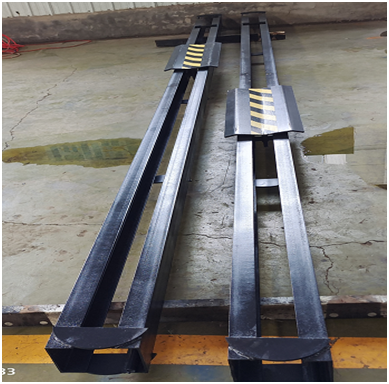

Ground rail trolley | 6 meters |

| |

Floor-standing preheating steel |

6 sets |

| The preheating cylinder has a diameter of 1000mm and an electric angle wrapping. |

Three-layer preheating steel |

1 set |

| The preheating cylinder has a diameter of 900mm and an electric angle wrapping. |

Single-sided corrugating machine |

2 sets |

| B+C corrugated two main machines, 340mm diameter, tungsten carbide corrugated roller, universal joint drive. |

Double-deck Bridge+Lifting Rectification |

1 set |

| Two sets of cardboard hoists Double-deck cardboard conveying bridge+1 set of double-deck automatic adsorption deviation correction, brand-new guardrail and brand-new conveying belt. |

Double coating machine |

1 set |

| Pneumatic paper pressing, heavy frame, rollers are in good condition, and cots rotate independently. |

Double-sided machine |

1 set |

| 18 hot plates, two large cotton belts, new grinding of hot plates, hydraulic adjustment and lifting. |

Thin knife longitudinal indentation machine

|

1 set |

| Computer control, computer list, 6 knives and 10 lines.

|

Computerized transverse cutting machine |

1 set |

| Computer servo, spiral knife, speed of 180 meters per minute. |

Cardboard stacker |

1 set |

| Automatic counting stacker |

Glue making system |

1 set |

| Three main tanks, plastic box and plastic pump. |